|

RUIAN DEVRY MACHINERY CO., LTD

|

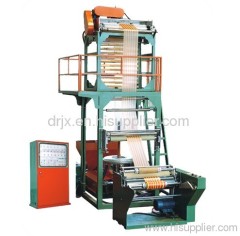

Three Layers Co-extrusion PE Film Blowing Machine

| Price: | 12000.0~22000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

3 layers pe film blowing machine:

1. suitable for LDPE, HDPE, LLDPE material;

2. prodcut main used as package material.

Three Layers Co-extrusion pe film blowing machine

Feature:

Feature:

1. Die head is layer type spiral mandrel, continuous 360 degree rotation.

2. Screen pack changer design is reliable, safe in operation and change the filter screen easier.

3. Various functional parts may be installed to the lies, such as length counting device, vertical cutting device, cooling water row pipe, film spreading roller, scrap collecting device.

4. It is optimum designed on the trounds of preference of analogous lines in foreign and home.

5. The lines holding temperature, anti-humid, anti-breeze, anti-rost, insulation oxygen, oil resistive, and used for light and heavy duty packaging, for example fresh fruits, meat feeding, salt vegetables, fresh milk, drink.

6. main motor, take-up motor and blower-motor are controlled by inverter

7. Die-head adopt spiral type structure, film structure: ABA, ABC, ABB, AAB

8. Various functional parts may be installed to the lies, such as air-shaft winder, length counting device, vertical cutting ,edge cutting , film smooth device and melt pressure sensing

9. Pneumatic cylinder to adjust the gap between take-up rollers

10. The tower is movable in height, driven by separate motor.

11. Material of screw and barrel: 38CrMoAlA; hardness of heat treatment: screw HV≥740, barrel HV≥900; depth of hardening:0.4-0.7mm; brittleness grade: ≤2 grade

12. Gear box: Surface heat quenching and tempering/auto. Oil lubricated

13. Die material: steel 45#/surface treatment of flow channel: hard chrome- plating

14. Digital display temperature controller

15. Power: AC 380V 3phase, control system 220v special power.

Main Machine part:

Main Machine part:

T-die gear box

Double rewind and cutter three screw one model co-extrusion

Main Technical Parameter

Model | 3SJ-G1200 |

Suitable for material | LDPE, HDPE, LLDPE, EVA, MLLDPE |

Diameter of screw | 60×2mm 65×1mm |

L/D of screw | 28:1 |

Screw and cylinder material | SCAM-645/38CRMOLA |

Rotational speed | 15-150r/min |

Power of main motor | 18.5kw×2 , 22 ×1 |

Screw speed | 150r/min |

Output | 120kg/h |

Range of die | 200mm 250×1mm |

Thickness of film | 0.008~0.20mm |

Max. folding width of film | 1200mm |

Electrical total capacity | 88kw |

Installing dimensions | 6800×4300×6000m |

Weight | 5T |

Related Search

Pe Film Blowing Machine

Pe Film Extrusion Machine

Co Extrusion Machine

Pe Blowing Machine

Extrusion Blowing Machine

Film Blowing Machine

More>>